Introduction:

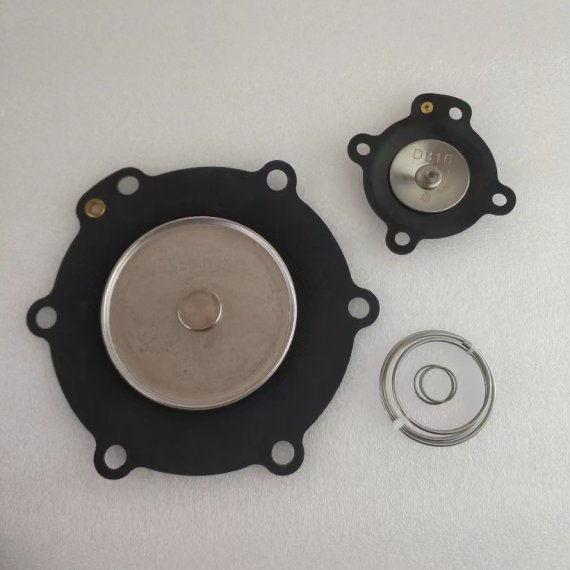

The diaphragm is the core component and primary wearing part inside a solenoid pulse valve. Its condition directly dictates the valve's performance, efficiency, and reliability. Recognizing the signs of a failing diaphragm is crucial for preventive maintenance, preventing unplanned downtime, and ensuring optimal system operation. Follow this professional 7-point checklist for a comprehensive diagnosis.

The Checklist:

Surface Wear: Inspect for Erosion

Carefully examine the diaphragm surface for any visible scratches, grooves, or thinning. This wear compromises the seal, leading to compressed air leaks and reduced pulse force. Replacement should be considered upon observing significant erosion.

Cracks and Tears: Check for Structural Failure

Look for any cracks, ruptures, or perforations, especially around the edges and central area where stress is highest. These are clear indicators of structural failure, meaning the diaphragm can rupture completely during the next cycle and requires immediate replacement.

Aging and Degradation: Assess Material Integrity

Check for signs of material degradation caused by heat, oxidation, or chemicals. Symptoms include hardening, brittleness, loss of elasticity, or surface micro-cracks. An aged diaphragm is prone to sudden failure and should be replaced preemptively.

Service Life: Adhere to a Preventive Schedule

The diaphragm's lifespan is directly tied to cumulative operating hours and cycle frequency. Maintain service records and implement a preventive replacement schedule once the expected service life is reached. This is the most effective strategy to avoid unexpected failures.

Acoustic Cues: Listen to the Valve's "Voice"

A properly functioning pulse valve produces a sharp, clean "snap" or "pop" during operation. Listen for changes such as a weak, hissing, or sluggish sound, which often indicate a torn, leaking, or sluggish diaphragm that can no longer form a tight seal.

Performance Data: Monitor Operational Parameters

Track key performance indicators like air supply pressure, pulse duration, and cycling intervals under normal conditions. Significant deviations, such as a need for higher pressure to maintain function or ineffective cleaning, can point to a fatigued diaphragm no longer providing an optimal seal.

Contaminant Buildup: Ensure a Clean Sealing Surface

Inspect for the accumulation of dust, oil, or crystallized media on the diaphragm surface. These contaminants act as a spacer, preventing the diaphragm from seating properly against the valve seat and causing continuous air leakage. Thorough cleaning or replacement is necessary to restore the seal.

Conclusion:

By integrating this diagnostic checklist into your regular maintenance routine, you can shift from reactive repairs to proactive care. Timely diaphragm replacement safeguards your system's reliability, optimizes compressed air consumption, and extends the overall life of your pulse valves.

Want to know more? Contact us to get the answers you need.

Ms Yanice Yu

Qingdao Star Machine Technology Co.,Ltd.

Whatsapp/ Wechat ID: +8617852092959

Email:Yanice@starmachinechina.com